Articles

Jan 07, 2019 - Is There a Way to Increase the Lifespan of My Gearbox?

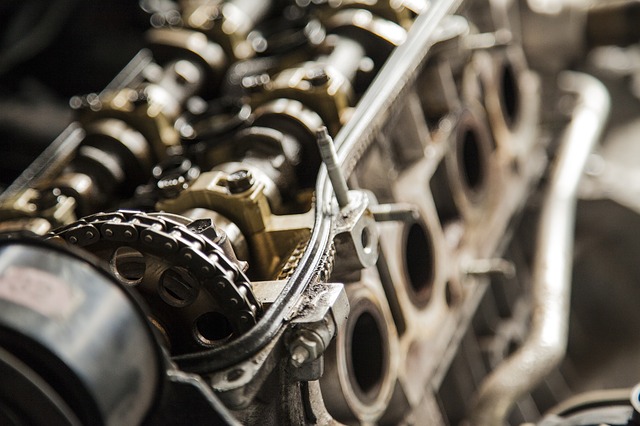

Industrial gearboxes are the heart and soul of power transmission systems. These units are strong enough to produce rotational energy by leveraging speed and torque (we serve 0 - 200,000+ ft-lbs) conversions. Effectively, gearboxes power other devices using gear ratios ranging from 1 to 500+ and come in different styles including Bevel, Helical, Helical Bevel, Helical Worm, Planetary, and Worm.

Gearboxes Are Essential to Keep Your Business on Track

Why are these devices so critical to your operations? They contribute immensely to manufacturing and operational productivity, albeit in extremely challenging work climates. Not only do they have to withstand general wear and tear, they also have to play well with demanding elements in an industrial setting; temperature variances, friction with neighbouring machinery, etc.

If you invest in a quality gearbox at the outset, you can be assured of several years of unhindered operability. From there, there are certain measures you can adopt to lend your gearbox an even longer lifecycle. This ensures that you save tremendously on replacement expenses.

In a previous article, we visited the common warning signs that indicate your gearbox is in dire need of repair. Each of those issues contribute to a greater problem when left unmonitored - such as a total system failure or shutdown.

In this article, we explore certain precautions you can take to mitigate those risks:

Routine Teeth Contact Inspection

Determine if the gear teeth are displaced from their actual position as it can be a primary cause of unwarranted noise. To measure tooth profile, you can use worm, bevel gear testers, gear tooth vernier calipers, and other measuring instruments. In parallel, you should follow this checklist of items to note down when recording:

-

Any traces of micropitting/macropitting at the tooth ends

-

Contact patterns without load

-

Contact patterns with load

Periodic inspections act as preventive measures for bearing failure and they assist in identifying the root cause of any potential problems with your gearbox.

Monitor and Observe Lubrication and Oil Levels

Make sure that you are using the right oil for lubricating your gearbox in order to avoid the after effects of high temperatures. For this, examine the oil you are currently using by undergoing tests to check viscosity, water, oxidation, ferrous density, any additives, metals, etc. Such oil analysis procedures can significantly limit the number of oil replacement and change times needed, thus reducing the overall cost of maintenance.

It is necessary that you select gearbox oil based on the following criteria:

-

Application or usage pattern

-

Operating temperatures

-

Additives selection

-

Viscosity levels

Insist on Cleanliness

Dust and dirt are also primary reasons behind excessive overheating of gearboxes. Ensure that you keep them clean in order to avoid any contaminants by conducting regular visual checks. Also, conduct physical inspections in order to look for areas with discolored or thin patches of paint as they also contribute to temperature variations in the gearbox.

Conduct a Periodic Vibration Analysis

By monitoring and analysing gearbox vibrations, you can determine whether the fault is caused by displacement or misalignment, bearing defects, teeth defects, loose internal bearings or any other problem. It is highly probable for the equipment to break down if the cause is left unattended for long.

Leading a proper maintenance plan and incorporating the above checks for your gearbox facility is fundamental to its operational efficiency. Failure to keep up with these can lead to quick wear and tear of the transmission units. However, if you do notice that your transmission units are run down, you should consider upgrading your existing transmission gearbox.

The Benefits of a Gearbox Upgrade

-

To increase processing speed

-

To enhance throughput and resource utilization

-

To improve load capacity according to changing needs

-

To reduce the risk of failure

-

To replace obsolete parts, revamp existing gear machinery and keep up with the new bearing technology

Don’t simply assume that your gearbox doesn’t require an upgrade. This could be penny wise and pound foolish. A quality system helps you reduce operational costs and makes regular repair redundant.

At Gordon Russell Ltd. our team of experts help solve this problem. We specialize in providing unmatched quality maintenance services to upgrade and support industrial power transmission systems/gearboxes. Our offerings include both in-house and onsite custom packages for inspections, overhauls and replacements to accelerate and optimize power transmission systems.

Tested and Recommended Gearboxes For Your Needs

Browse through our range of gearboxes and find one that matches your needs. We stock plenty of gear styles (bevel, helical, planetary, worm, etc.) from industry leading suppliers. Our onsite and in-house professional services include; drive inspections, overhauls, and replacements.

At Gordon Russell, we provide quotes that simply can’t be beaten. Put us to the test! Contact us at (604) 940-1627.

Web Design & Development by Web Masters Corp.