Articles

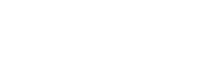

Aug 03, 2018 - Eaton Airflex Clutches and Brakes For the Most Demanding Applications!

When it comes to the control and transmission of torque and speed in drivetrain systems, clutches and brakes play a monumental role. They operate by passing the torque from the input shaft to the output shaft through clutching or braking to hold and stop the load. Although they are available as separate components, their functionality is often combined together in a single unit.

Things to know about industrial clutches and brakes

When in operation, the clutches and brakes transmit energy between an input and output shaft via the point of contact. The transmitted energy which turns into heat is equivalent to the energy absorbed from or imparted to the load. The engagement or point of contact is electromagnetic, mechanical or friction lockup, and can accommodate a diverse array of configurations such as caliper, drum and disk.

In addition to various designs and interfaces, clutches and brakes come with different actuation forces as well that determine the action of the interface, including hydraulic, pneumatic, self-actuation, electric and mechanical. So when you are looking for the right type of clutches and brakes for your specific requirements, actuation and engagement can make two important comparison parameters.

Eaton Airflex Clutches and Brakes

If you’re digging the industrial marketplace for superior quality clutches and brakes that can deliver excellent performance and long life, Eaton Airflex lineup is just what you need to look into. Its product selection encompasses a multitude of options in terms of engagement, release style and type. So once you’ve identified what befits your application, it won’t be difficult to find that in Eaton Airflex collection of clutches and brakes. Designed to perform in the most rigorous conditions, Airflex brakes are procurable in different categories including air-cooled disc, caliper disc brake, combination clutch/brake, spring applied drum, expanding, constricting and water-cooled style.

Gordon Russell is an authorized distributor of a broad variety of industrial power transmission and control products such as Eaton Airflex clutches and brakes.

WCSB Combination Brake for Heavy-Duty Applications!

The air-applied WCSB range of brakes from Eaton Airflex is impressively engineered to excel in the harshest tensioning and braking activities. The WCB element ensures static holding, dynamic tensioning and quick stopping in emergency situations. Existing in a range of torque and thermal capacities, these brakes are well suited for log yarders, mooring systems, draw works and other heavy-duty equipment.

Eaton Airflex Water-Cooled Third Generation Brake

It‘s an externally water-cooled, disc type brake to handle extremely high thermal loads. Available with a dual piston design, this device complies with the corrosion resistance standards and yields high coolant flow with 60% lower pressure drop. The self-supporting brake does away with the cost incurred due to the support brackets. Easy to maintain and install, it does not require any matching of friction and wear plates. The robust design makes it just the right option for demanding applications where even the most competitive units would fail and experience copper cracking. Moreover, this brake can be readily deployed in retrofits to existing WC brake mounting.

CBC Spring-Applied Brake

If yours is a high-cyclic application that demands high speed, Eaton Airflex CBC brake is the best fit. Whether you’re going to integrate it into an existing system or a new one, this brake will render the best results in terms of both flexibility and performance. It features a spring-applied disc brake and air-actuated disc clutch that can be readily mobilized for printing machines, automatic punching machines, woodworking machines, shears and more. The variety of sizes is huge and so is the range of the clutch/brake capacities, which means you don’t have to look anywhere else for your discerning requirements.

Here is an infographic for an in-depth information on the above-mentioned Eaton Airflex clutches & Brakes:

What to consider when deciding on the right option?

Each application is different and your selection may hinge on various factors, such as maximum torque, maximum operating speed, response time, thermal capacity, cycle rate, weight or space restrictions, the need of routine maintenance, and acceptable service life. Bear in mind that the characteristics such as envelope size, response time, torque, repeatability and control medium are affected by brake or clutch geometry, actuation force and interface.

The air-cooled brakes and clutches offer quick response and have no energy consumption or heat generation throughout the long periods of engagement. A reason why they are widely used is that most plants generally have compressed air systems which can supply air at 80 psi - perfect for the operation of brakes and clutches.

Ensure your drivetrain system integrates the best clutch/brake combination package to realize superior overall performance.

Contact Gordon Russell to request a quote on your industrial equipment requirements!

Web Design & Development by Web Masters Corp.